Nothing is more frustrating than setting up a shrink wrapper and having the package exit the shrink tunnel with cosmetic issues. Experienced operators know that an imperfect package provides clues on adjusting the system set-up to correct the issue. All you have to do is look at the film.

Al Kiggans, Texwrap’s resident shrink wrapping expert, explains the potential cause behind six of the most common film issues including burnout and pinholes, as well as set-up adjustments that generally correct the issue.

Three variables affecting shrink film results

Before looking at those six common problems, it’s important to understand the variables that affect the shrink process. These three variables are: bag size, air evacuation/perforations and tunnel temperature or speed.

Let’s look at how these three variables affect the film.

- Bag Size

During the shrink process, the bag must be large enough to allow the film to balloon away from the product and collapse just prior to exiting the tunnel chamber. If the bag size is to tight, the film will come in contact with the product too soon causing fish-eyes or crow’s feet. The film must balloon away from the product first then collapse.

- Air Evacuation (Perforations)

Letting the air out too fast does not allow the film to balloon properly resulting in wrinkles, crows’ feet, or fish eyes. Letting the air out too slowly causes bubbles, cloudy film, and potential burn outs. Placement of perforations – controlling which part of the bag retains the air longest can help control the shrink. The most critical element for package appearance is in controlling the air evacuation!

- Tunnel Temperature & Speed

For good package appearance you need to have 3 to 4 seconds of time in the tunnel chamber. The size of the tunnel is dependent on production rates. Always adjust the tunnel conveyor speed and temperature so that the balloon of the film will collapse just prior to exiting the tunnel chamber.

Six Common Film Issues

Now that we have an understanding of the three most important variables in the shrink process, let’s take a look at how incorrect machine or film set-up can be seen in the final package, the most common cause, and how correct the issue by adjusting the setup.

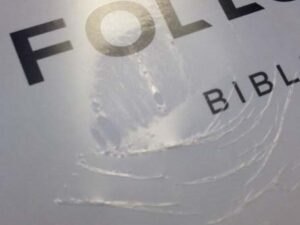

Burnout

- BURNOUT: Holes or breaks in the film not associated with the seam

- COMMON CAUSE: Insufficient air evacuation

- ADJUSTMENT: Add some perforations so heat escapes more quickly

Cloudiness

- CLOUDINESS: Film is foggy/not clear

- COMMON CAUSE: Tunnel temperature is too hot

- ADJUSTMENT: Adjust the temperature, or try speeding up the conveyor. You may also need to add some perforations.

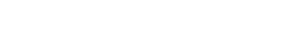

Crows Feet

- CROWS FEET: Wrinkles at corners and near edges

- COMMON CAUSE: Improper bag size – bag is too small, or too many perforations

- ADJUSTMENT: The bag must balloon away from the product during the shrink process. Adjust the bag size and remove some of the perforations.

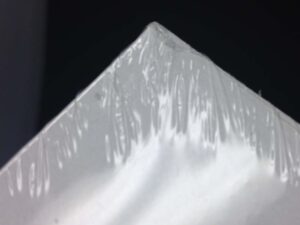

Dog Ears

- DOG EARS: Puckered film sticking out at end of the seal

- COMMON CAUSE: Improper bag size, too many perforations, and time and temperature in the tunnel

- ADJUSTMENT: Make adjustments to ensure the bag has 3 to 4 seconds of dwell time inside the tunnel chamber.

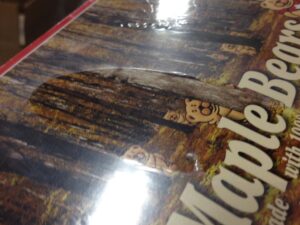

Fish Eyes

- FISH EYES: Roundish blemishes near edges

- COMMON CAUSE: Improper bag size and/or too many perforations

- ADJUSTMENT: The bag must balloon away from the product during the shrink process. If there are too many perorations the bag will not inflate properly, or if the bag is too small, it will come in contact with the product too quickly. Adjusting the bag size and removing some of the perforations will help.

Pin Holes

- PIN HOLES: Small holes along the seal

- COMMON CAUSE: A setup issue where there is too much tension on the film during the sealing process

- ADJUSTMENT: Try making a bigger bag size and relaxing the film.

Conclusion

Learning to read the film signs and adjust the bag size, perforations, and tunnel settings appropriately are the keys to secure shrink film containment and flawless presentation.

Be sure to learn more about troubleshooting shrink systems in the article, Troubleshooting End Seal Issues.

If you have questions email us at Texwrap@promachbuilt.com, or call 636-239-2474.