When a line completes a changeover between SKUs or rolls of film, the process should look like a NASCAR pit stop. Machine operators trained to perform changeovers make the necessary adjustments with speed and accuracy, then get everything back on track without making a major impact on performance. Achieving this level of efficiency for equipment changeovers requires a balance between employee skill, machine capabilities, and required throughput. However, as staffing shortages continue to impact most sectors of manufacturing tasks, such as a changeovers, have become more challenging to complete. This is coupled with the growing demand many companies are seeing for their goods, requiring packaging lines to operate at peak efficiency with minimal downtime. In these situations, operators may need their machinery to shoulder more of the load.

Texwrap offers three system enhancements to its shrink wrapping and bagging machines that can help make the systems more user-friendly and reduce downtimes from changeovers.

1. Changeover Assist Package

Instead of taking the time to individually modify each changeover part, the Changeover Assist Package allows users to store a collection of recipes that drive automatic adjustments to all components at once. This includes the inverting bar, film feed, side seal conveyor, end seal height, tunnel controls integrated in the wrapper and other features. An automatic system decreases the downtime and labor required to change the machine between SKUs while eliminating micro steps and the possibility of error from manual adjustments.

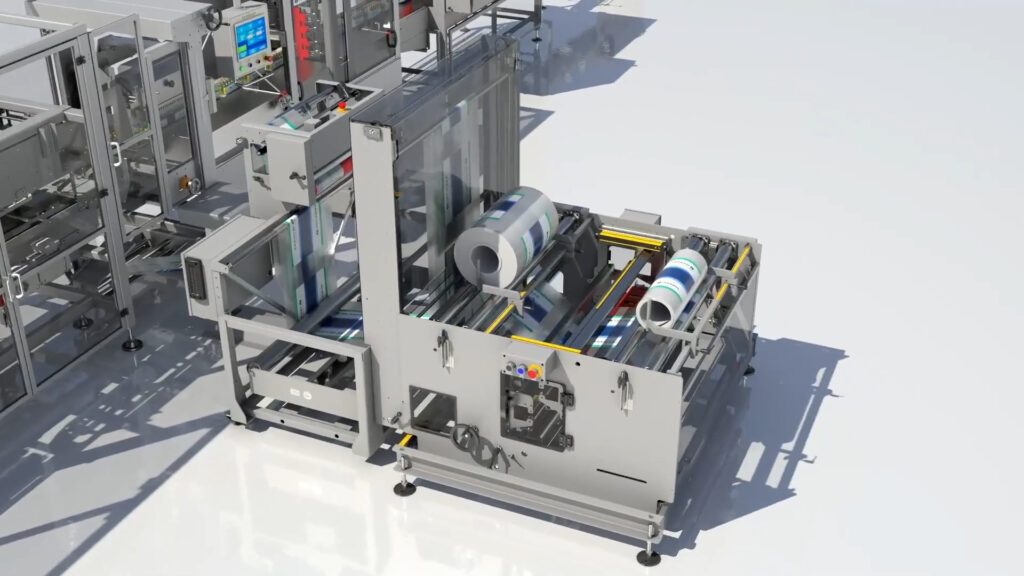

2. Automatic Film Splicer

In addition to changeover between product types, packaging machines often experience costly stoppages when employees need to swap out rolls of film. To combat this issue, Texwrap offers the Automatic Film Splicer, which can splice clear or printed films without stopping or even slowing production. Adding this to a Texwrap machine reduces labor and eliminates time requirements of roll-to-roll changes for an overall increase in productivity.

3. Manual Film Splicer

Another option that has proven to be one of Texwrap’s most popular is the Manual Film Splicer. This solution uses single wound film with twice the footage per roll compared to center folded film to double the output per roll and cut changeovers in half. For operations with fewer staffing issues, this can be a cost-effective way to increase throughput capability.

To talk to a sales team member about these and all the other features that make Texwrap a valuable addition to your end-of-line packaging, visit our “Contact” page to find a rep and get started.

Al Kiggans is the Midwest Regional Sales Manager for Texwrap (www.texwrap.com). He can be reached at al.kiggans@promachbuilt.com.