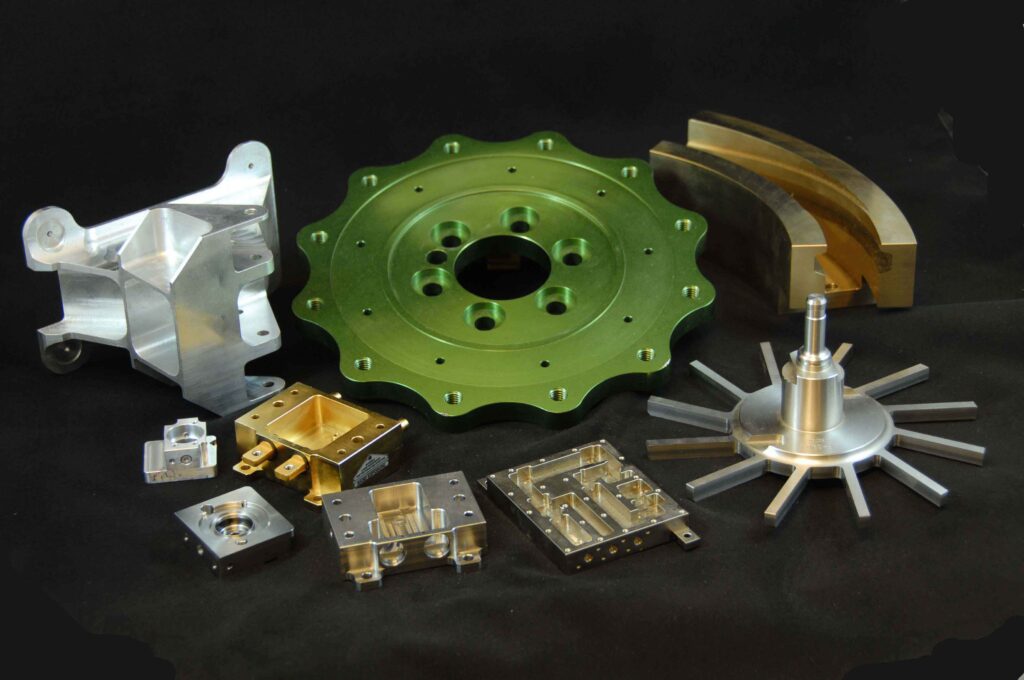

One of the many things that sets Texwrap machinery apart from the competition is something that tends to get overlooked: in-house fabrication.

Fabricating parts at our facility in Washington, Missouri, helps customers get the most from their Texwrap packaging system and realize long-term success.

For starters, we use some of the most advanced metal fabricating equipment and techniques to manufacture parts to exact tolerances. By not relying on outside, third-party vendors for parts, we have complete control over the quality of every component that goes into the machines we build.

This control extends from initial concept, through the factory acceptance testing (FAT), to installation and beyond. We design, machine, assemble, program, and test our equipment all under one roof. If plans change and modifications are needed, we can quickly make those adjustments right here, giving our customers full confidence that their system will operate as expected. This really aides in streamlining communication and keeping projects on-time and within budget.

In-house fabrication also works to minimize equipment downtime. When replacement parts are needed, our talented metal fabrication team manufactures them to the exact specifications and gets them shipped within a day or two – sometimes on the same day – to keep production rolling as smoothly as possible.

What this all means is peace of mind in knowing the system is designed and managed correctly from start to finish by in-house experts; we manufacture equipment with the lowest total cost of ownership available on the market today. Furthermore, we stand by our craftsmanship in giving a fantastic 10-year warranty on all Texwrap manufactured components.

We work hard for our customers, and bringing them all the benefits of in-house fabrication is just one of things we do to earn their business.

Al Kiggans is a Regional Sales Manager for Texwrap Packaging Systems. He can be reached at Al.kiggans@promachbuilt.com; https://www.texwrap.com/.